-50%

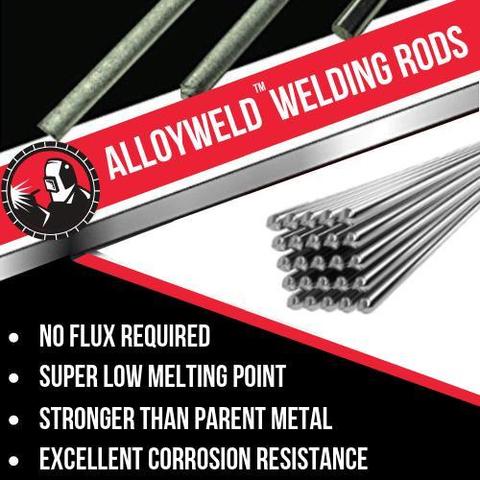

EASY MELT WELDING RODS—NO NEED WELD POWDER

$17.99 – $39.99

Introducing The Simplest Way To Weld Aluminum Parts – No Expensive Equipment Required. You only need one propane torch and some Easy Melt Welding Rod.

FEATURES:

- No need for flux, very convenient to use.

- These electrodes form a good joint that is stronger than the base metal and allows thin, thick parts to be joined together.

- It has very good corrosion resistance and little or no deformation to the base metal.

- Recommended for welding or brazing aluminum alloys and casting alloys

- Applications include truck beds, loading ramps, docks, diamond plates, irrigation piping, engine blocks, transmission housing, etc.

- Low-temperature aluminum welding wire can weld almost all white metals.

- It includes dissimilar welding between steel, iron, aluminum, aluminum alloy, cast aluminum, aluminum-magnesium alloy and the above metals.

- even for white metals that have been seriously corroded or contaminated with oil, even those that are considered irreparable.

- Aluminum alloys can be repaired.

WELDING INSTRUCTIONS:

- Thoroughly clean the area you’re about to weld by brushing the base with stainless steel brush until it becomes shiny. Then evenly heat the area to be welded.

- As you heat, rub the rod vigorously against the heated area until the rod starts flowing.

- Please Note: Never apply heat directly to the rod as it will crumb, and if you manage to melt the rod directly, the weld will be easily breakable. Remember, melting the rod directly is a wrong way, and makes crumby welds.

Package Includes:

- 10 pcs Easy Melt Welding Rods

- 20 pcs Easy Melt Welding Rods

- 50 pcs Easy Melt Welding Rods

SPECIFICATIONS:

- Material: Aluminum-magnesium

- Melting temperature: < 896°F (480°C)

- Application: Aluminum and aluminum alloy welding/brazing

- No emitting of gases or toxins, No Lead content included.

- Excellent corrosion resistance.

- Minimize parent material distortion during welding.

- Length: 19 inches.

Bernard –

Just 5+